- What is the material requirement planning system?

- What is a manufacturing resource planning system?

- What are the benefits of MRP?

- What are the benefits of MRP II?

- What is the connection between MRP, MRP II, and ERP?

- What does your business need?

What is the material requirement planning system?

Material requirement planning or MRP enables manufacturers to manage their manufacturing inventory by scheduling and planning. It is also called a type of inventory management system. MRP specifies what components are needed for production, how many materials are needed, and when they are required. This allows manufacturers to have the materials required for production and ensures the materials are produced at the scheduled date. The aim of MRP is to boost production efficiencies by ensuring no raw materials and components are sitting idle. It maintains the minimum inventory levels required so production can start.

It takes in raw data and processes it for manufacturers to get a clear picture of what is required for timely production to take place. The input to the material requirements planning software includes BOM or bill of materials. This bill contains details of components and raw materials required if the product needs repair or if it needs to get manufactured. MRP started in the 1960s and today has come a long way in enabling businesses to get a hold of their manufacturing capabilities while reducing wastage in the process. Today, MRP software works seamlessly to ensure supply and demand are balanced so that manufacturers have sufficient stock. This was a challenge in its early days.

|

Bill of Materials (BOM) – Definition, Examples, Format and Types |

Audited Financial Statements: – Definition, Inclusions and Auditors Report |

What is a manufacturing resource planning system?

Manufacturing resource planning system or MRP II was born as an extension of the MRP system. During the 1980s, many manufacturers needed more than what the traditional MRP offered. They wanted to include details of labor and finances. This is when the manufacturing resource planning system was developed. It includes what the material requirement planning system has along with financial requirements and employee data. Today, many manufacturers continue to use MRP II because it is still offered as a stand-alone solution. Manufacturing resource planning system is also offered as a part of an ERP software solution for manufacturers.

Manufacturing resource planning software has the goals of material requirement planning which is to control cost, manage inventory, and make scheduling easy. But it also has additional goals. MRP II makes it easier for manufacturers to streamline their manufacturing processes because now they can also know how many people are required and what costs are needed to ensure proper production. Manufacturing resource planning systems encourage finance, marketing and production teams to work together. They are required to make changes to the plan when needed and this can vary from manufacturer to manufacturer. Some may need to make changes weekly, while others may have more time at hand.

What are the benefits of MRP?

Material requirement planning or MRP benefits are as follows.

Inventory management: MRP enables manufacturers to manage their inventory levels effectively. Overstocking and understocking plague businesses of all sizes. Understocking means you won’t have enough which will keep customers fuming. Overstocking can add to costs and damage your bottom line. MRP ensures proper inventory management to ensure sufficient inventory is always available.

Effective resource management: Every business needs to manage its resources to ensure minimal wastage. Material requirement planning software ensures resources are being optimally utilized. Manufacturers know how much is required and when. This makes it easier to make plans to ensure everything goes as per schedule and changes can be made if required.

Production planning: A business should not perform tasks without a solid plan first. MRP encourages manufacturers to come up with a plan for optimal efficiency. Production planning is made easier and streamlined with a MRP system in place. Manufacturers know their production schedules and this ensures they can keep their customers satisfied.

Cost reduction: Overstocking means higher costs and if it is a perishable item then it can add to your costs. When material requirement planning is used, costs are decreased because you are aware of what you require. This level of clarity ensures you have enough without running out. Costs are also reduced because you don’t have excess of one component and a lack of another. MRP ensures balance occurs.

Saves time: A MRP system saves manufacturers considerable time as they don’t have to manually calculate the right inventory levels. Planning is made easier with the software and though input from the production manager is required, it cuts down on the burden that is placed entirely on the production team. It saves time so that you can spend it on other important tasks.

What are the benefits of MRP II?

MRP II has all the benefits of MRP with the addition of the following advantages.

Forecasting capability: MRP II software comes with the ability to forecast better than a MRP system. This allows you to make a more accurate plan of what is required and to schedule so production is always going smoothly without any glitches. The forecasting function also means you can more accurately place orders for components required well in advance.

Integration of financials: MRP II adds the integration aspect. Knowing how much it will cost you to have extra labor is critical to planning. MRP II makes financials a core component of resource planning so that it is not an after-thought. This enables you to plan more in-depth and know how much production is costing you without discrepancies. That is, it throws light on cost accounting.

Labor management: As a manufacturer, you must know how you are utilizing labor. MRP II improves the efficiency of labor capacity planning. This means you are made aware of how much labor is required for production, the associated costs, and the time it will take for the production to be complete. You will then know whether you need to improve labor capacity or not.

Coordination of departments: In MRP, the focus is on the manufacturing department. However, in MRP II, things start to change because it integrates and coordinates other departments too. This coordination of departments enables better decision making and a broader outlook that is more beneficial to the business. MRP II takes additional input which improves its accuracy to new levels.

What is the connection between MRP, MRP II, and ERP?

MRP, MRP II, and ERP are related to each other because they are extensions of the previous system that was rolled out. Material requirement planning came first followed by MRP II. ERP is the successor of MRP II. Each built upon the previous to add more functionality and give better control to manufacturers so they can improve production efficiencies. Material requirement planning is all about ensuring correct inventory levels, timely deliveries, and improving manufacturing efficiency. Manufacturing resource planning includes all that MRP systems include and integration of other processes such as financials and employees. ERP encompasses the functions of MRP and MRP II.

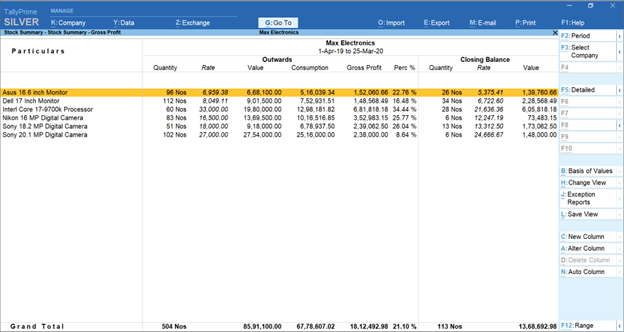

Stock summary with profitability details in TallyPrime

Stock summary with profitability details in TallyPrime

ERP software adds more functionality by ensuring the various systems of a business work together cohesively for optimal planning, cost reduction, and resiliency. While MRP is not in use today, MRP II and ERP systems are still in use. Generally, ERP and MRP II are used in conjunction by businesses for maximum benefits. However, as ERP software solutions are getting increasingly advanced, they are being utilized by more and more businesses across numerous industries. ERP software is the most sophisticated out of the three as it improves transparency by merging processes with data to give you insights you can act upon. ERP software enables businesses to respond and adapt to market changes.

What does your business need?

Do you need just the inventory management software or should you get a robust system such as an ERP suite? The answer lies in your requirements. If you are a growing business, then you need to adapt to market changes to sustain yourself and so ERP software such as TallyPrime is required. ERP software can integrate all of the different silos so that you work in a unified system that can further improve your business growth in the future. ERP systems can improve processes across your business so that every aspect of it is working optimally.