- What is Bill of Material (BOM)?

- Format of Bill of Materials

- Type of Manufacturing Industries which uses Bill of Material

- Different types of Bill of Material (BOM)

- Format of Cost Estimation using Bill of Material

- Examples of Bill of Material (BOM)

Bill of Material more popularly known as ‘BOM’ is a key function of businesses who are engaged in manufacturing inventories. Bill of Material (BOM) helps the manufacturing unit to design, plan inventories, determine cots estimation etc.

In this article, let us understand the bill of material (BOM) right from definition to different types of BOM with examples.

What is Bill of Material (BOM)?

Bill of Material is a comprehensive list of raw materials, components, assemblies, sub-assemblies, parts, or anything which is required to manufacture the finished product. The finished product or goods may be the final product itself or a semi-finished product which is later consumed to produce a final or a larger product.

The bill of material for finished goods not only lists the components but also the quantity of each component required to produce the finished goods. If the finished product has a variant by colour, configuration, size etc., you can choose to have multiple BOM for a single product. The examples in the next section will help you understand this easily.

Also, if the production of finished products leads to the production of by-product/co-product or scrap, this can be defined in the bill of material.

Format of Bill of Materials

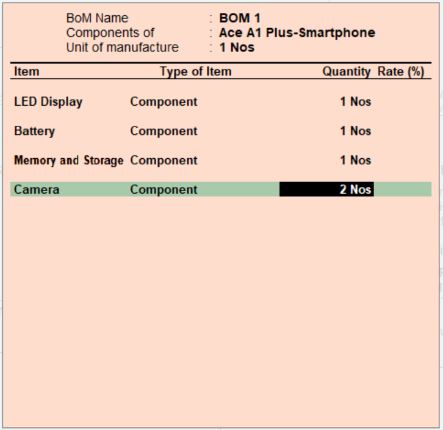

The format of bill of materials varies but it contains the essential details as discussed in the above sections. Below is the simple and easy to use bill of material format.

Type of Manufacturing Industries which uses Bill of Material

Having understood the definition with the examples, you must have got the hints of manufacturing industries which potentially can use a bill of material. Largely, the bill of material is used in discrete manufacturing industries.

Here, discrete manufacturing implies that finished products are made of components or raw materials that are capable of being touched and counted. This includes joining, attaching, fixing, assembling etc. and finished products produced here are capable of being broken down and disposed it as parts or re-use it.

There is no use or minimum use of a bill of material in process manufacturing industries. Ketchup, cosmetics, Paints, Juices etc. are examples of process manufacturing industries

Different types of Bill of Material (BOM)

The following are the different types of Bill of Material (BOM)

- Assembly Bill of Materials

- Configurable BOM

- Single-Level BOM

- Multi-Level BOM

- Engineering Bill of Materials (EBOM)

- Manufacturing Bill of Materials (MBOM)

- Service BOM

- Sales BOM

Among the several types of bill of material, the following are the important types of BOM.

- Engineering Bill of Materials (EBOM)

- Manufacturing Bill of Materials (MBOM)

Engineering Bill of Materials (EBOM)

The engineering bill of material is either based on the Computer-Aided Design (CAD) or Electronic Design Automation (EDA) and is created during the design phase of the product. This provides the complete list of the components or parts as designed by the engineering team.

Manufacturing Bill of Materials (MBOM)

This is the actual list of components required to produce the finished products along with the quantities. This is the list which is used by the procurement department to maintain the stock and also to update the ERP system with BOM details.

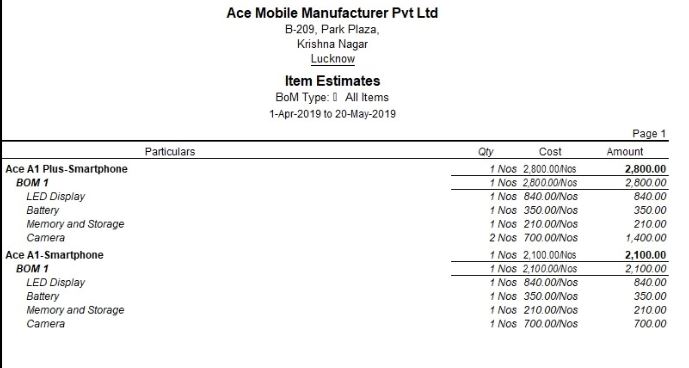

Format of Cost Estimation using Bill of Material

One of the greatest outcomes of using the bill of material is its ability to produce the cost estimation. This considers the list of components defined in BOM of finished products and allows you to generate the cost estimation.

Automated Cost Estimation Report generated using Bill of Material in Tally.ERP 9

Examples of Bill of Material (BOM)

As the definition says BOM is nothing but a complete list of raw material/components to produce a final product, let us consider an example of a finished product which requires few components to produce the finished goods. The example we are considering here is of the Mobile phone which requires components to produce the finished product.

Ace Mobile Manufactures Pvt Ltd. manufactures following 2 Mobile phones and would like to create the bill of material for both the products.

- Ace A1 Smartphone

- Ace A1 Plus Smartphone

Example -1: Bill of Material of Ace A1 Smartphone

|

Bill of Material of Ace A1 Smartphone (To produce 1 Nos of Finished Product) |

||

|

Type of Product |

Name of Inventory |

Qty |

|

Components |

LED Display |

1 Nos |

|

Components |

Battery |

1 Nos |

|

Components |

Memory and Storage |

1 Nos |

|

Components |

Camera |

2 Nos |

|

Components |

Processor |

1 Nos |

|

Components |

Motherboard |

1 Nos |

|

Components |

Microphone |

1 Nos |

|

Components |

Speakers |

1 Nos |

|

Components |

Blue Panel |

1 Nos |

Illustration of Bill of Material

As illustrated above, to produce 1 no. of Ace A1 Smartphone, the tables tell you the list of components required along with the quantity. Except for camera (2 Nos are required) all other components are required 1 Nos. per finished goods.

Example -2: Bill of Material of Ace A1 Plus Smartphone

|

Bill of Material of Ace A1 Plus Smartphone (To produce 1 Nos of Finished Product) |

||

|

Type of Product |

Name of Inventory |

Qty |

|

Components |

LED Display |

1 Nos |

|

Components |

Battery |

1 Nos |

|

Components |

Memory and Storage |

1 Nos |

|

Components |

Camera |

4 Nos |

|

Components |

Processor |

1 Nos |

|

Components |

Motherboard |

1 Nos |

|

Components |

Microphone |

1 Nos |

|

Components |

Speakers |

1 Nos |

|

Components |

Blue Panel |

1 Nos |

Illustration of Bill of Material

As illustrated, the above is the BOM of Ace A1 Plus Smartphone and the only difference here is you need 4 cameras to produce the final product.

Example -3: Multiple Bill of Material for Single Product

Let’s say, Ace Mobile Manufactures Pvt Ltd manufactures these 2 smartphones in different colours such as Blue, White and Black. In such situations, you can define multiple Bill of materials (BOM) for single product.

In this case, a single finished product ‘Ace A1 Plus Smartphone’, you can have 3 bill of material, namely Blue, White and Black as shown below.

|

Bill of Material of Ace A1 Plus Smartphone (To produce 1 Nos of Finished Product) |

||

|

Bill of Material Name: Blue |

||

|

Type of Product |

Name of Inventory |

Qty |

|

Components |

LED Display |

1 Nos |

|

Components |

Battery |

1 Nos |

|

Components |

Memory and Storage |

1 Nos |

|

Components |

Camera |

4 Nos |

|

Components |

Processor |

1 Nos |

|

Components |

Motherboard |

1 Nos |

|

Components |

Microphone |

1 Nos |

|

Components |

Speakers |

1 Nos |

|

Components |

Blue Panel |

1 Nos |

|

Bill of Material of Ace A1 Plus Smartphone (To produce 1 Nos of Finished Product) |

||

|

Bill of Material Name: Black |

||

|

Type of Product |

Name of Inventory |

Qty |

|

Components |

LED Display |

1 Nos |

|

Components |

Battery |

1 Nos |

|

Components |

Memory and Storage |

1 Nos |

|

Components |

Camera |

4 Nos |

|

Components |

Processor |

1 Nos |

|

Components |

Motherboard |

1 Nos |

|

Components |

Microphone |

1 Nos |

|

Components |

Speakers |

1 Nos |

|

Components |

Black Panel |

1 Nos |

|

Bill of Material of Ace A1 Plus Smartphone (To produce 1 Nos of Finished Product) |

||

|

Bill of Material Name: White |

||

|

Type of Product |

Name of Inventory |

Qty |

|

Components |

LED Display |

1 Nos |

|

Components |

Battery |

1 Nos |

|

Components |

Memory and Storage |

1 Nos |

|

Components |

Camera |

4 Nos |

|

Components |

Processor |

1 Nos |

|

Components |

Motherboard |

1 Nos |

|

Components |

Microphone |

1 Nos |

|

Components |

Speakers |

1 Nos |

|

Components |

White Panel |

1 Nos |

Here, we have 3 bill of material (BOM) for A1 Plus Smartphone and only difference here is the panel colour. Similarly, you can have 3 different BOM for A1 Smartphone based on the panel colour.

Watch this Video to Know How to Create and Use BoM for Manufacturing in TallyPrime

Explore More Products