- What is Inventory Audit?

- Importance of Inventory Audit

- What are the procedures for auditing inventory?

What is Inventory Audit?

Auditing inventory is the process of cross-checking financial records with physical inventory and records. It can be completed by auditors and other parties. An auditing inventory can be as simple as just taking a physical count of stock and inventory to match the records with physical stock.

Auditing is the process of verifying that the financial records of an entity are accurate and fairly represented. Transactions in financial records must fairly represent the entity’s financial positioning and actual operating activities.

Since financial documentation and records are produced internally, there is a high risk that records can be manipulated by inside parties. Insiders can make mistakes or intentionally alter information while preparing financial records, which is considered fraudulent behaviour. Auditing ensures that these mistakes are prevented.

Audits also ensure that entities are complying with relevant accounting standards such as the International Financial Reporting Standards (IFRS), Generally Accepted Accounting Principles (GAAP), and other relevant accounting standards.

Importance of Inventory Audit

- Inventory audit is also required to match the actual quantity of items in stock against the accounting records while also adjusting for differences and allowing for shrinkage so that the ledger reflects accurate values

- Inventory audit will be able to reveal which physical goods or products are over- or under- stocked. This will allow you to properly and effectively stock your business thus helping maximize profit

- Inventory audit is necessary to reduce unnecessary investment on stocks and to ensure that you have a proper line balancing in the process

- Inventory audit is needed to compare actual physical counts and match it to business records: When this count is conducted accurately, an inventory audit will be able to disclose the true picture of what you actually hold as compared to the recorded stocks which, in turn, will give you an understanding of the financial health of the company. Misstatement of inventory balances often tends to have a direct effect on reported profit

- Inventory audit is imperative to account for any sort of inventory losses resulting from, wastage, pilferage, damage, obsolescence, and dormant stock

- An inventory audit will also help determine the effectiveness of your warehouse procedures and help reveal any issues within your organisation’s warehouse procedures, whether it is at the receiving dock or during the actual packaging. This could help in highlighting any potential inefficiencies in the process such as disorganisation of the warehouse and slow retrieving methods

- Inventory audit will help reveal any failure owing to lack of security which results in loss, theft or misappropriation

- High levels of stock generally result in unnecessary overstocking thus resulting in poor cash flows and financial loss. An inventory audit at timely intervals will help remedy that issue. Similarly, it helps in determining any obsolete inventory in stock or orders incorrectly supplied to customers which could not only lead to financial loss but also result in an irreparable damage to the organisation’s reputation

What are the procedures for auditing inventory?

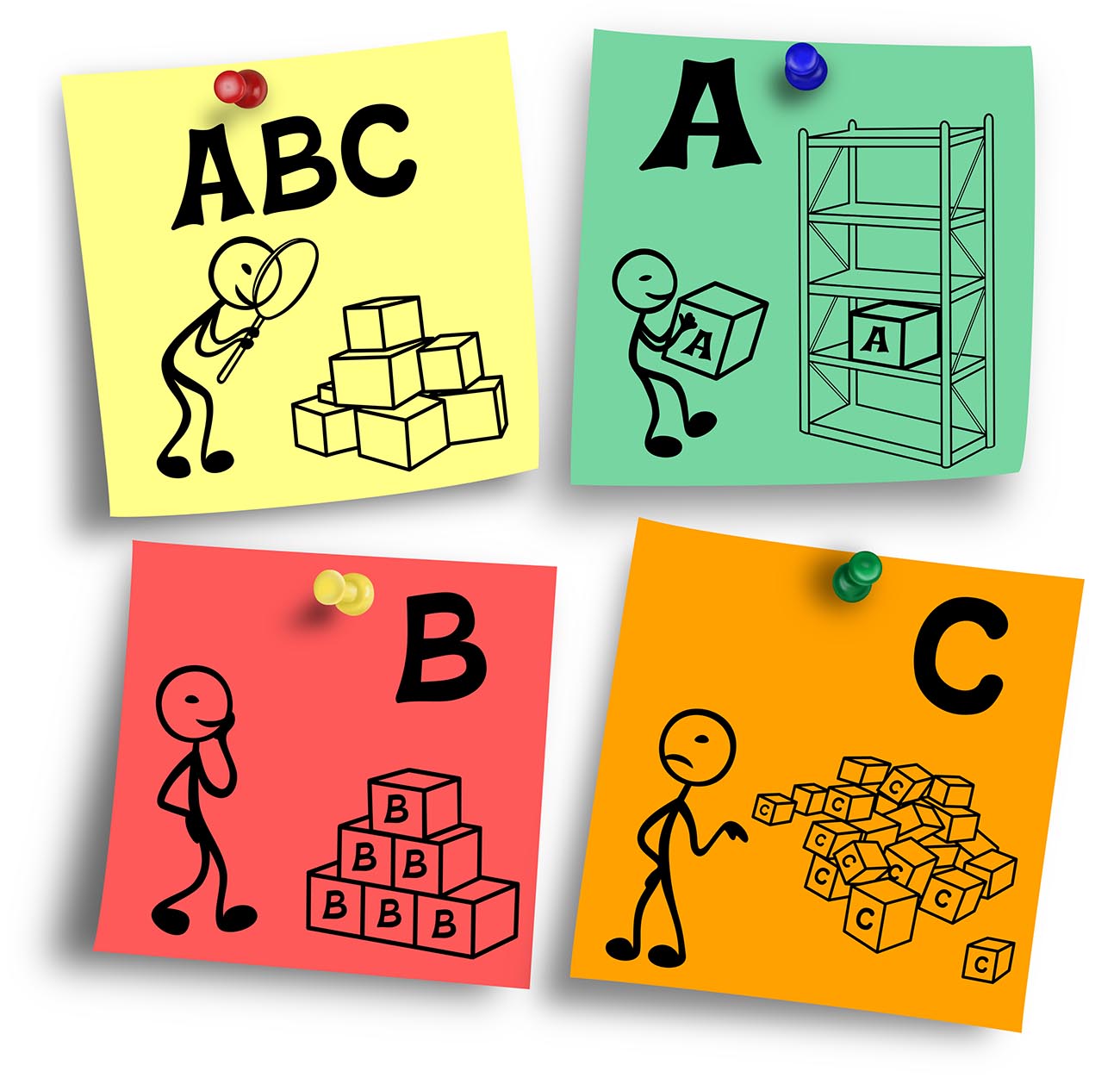

ABC analysis

An ABC analysis includes grouping different value and volume inventory. For example, high-value inventory, mid-value, and low-value products can be grouped separately. The items can be tracked and stored in their separate value groups as well.

Analytical procedures

Analytical procedures include analyzing inventory based on financial metrics such as gross margins, days inventory on hand, inventory turnover ratio, and costs of inventory historically.

Cut-off analysis

The cut-off analysis includes pausing operations such as receiving and shipping of inventory while making a physical count to avoid mistakes.

Finished goods cost analysis

Finished goods cost analysis applies to manufacturers and includes valuing finished inventory during an accounting period.

Freight cost analysis

Freight cost analysis includes determining the shipping or freight costs for transporting inventory to different locations. Generally, freight costs are included in the value of inventory, so it is important to track the freight costs as well.

Matching

Matching involves matching the number of items and the cost of inventory shipped with financial records. Auditors may conduct matching to verify that the right amounts were charged at the right time.

Overhead analysis

Overhead analysis includes analysing the indirect costs of the business and overhead costs that may be included in the costs of inventory. Rent, utilities, and other costs can be recorded as part of inventory costs in some cases.

Reconciliation

Reconciliation includes solving discrepancies that are found in an auditing inventory. Errors may be re-checked and reconciled on financial records.

Read More on Inventory Management

Inventory Management, Inventory Management Software, Inventory Management Techniques, Inventory Reports, Inventory Planning, Inventory Valuation, Inventory Control, Inventory Turnover Ratio, Importance & Benefits of Inventory Management, What is a Barcode, What is Physical Stock Voucher, Stock Query and Its Benefits, How Godown Summary Helps in Better Inventory Management, What is Stock-Item Wise Profitability