- Importance to keep your warehouse at its best

- Tips to maintain your warehouse

- How organising and tracking inventory at warehouse helps?

- Does inventory management software help you manage inventories at warehouses?

Warehousing is the storage of manufactured products or goods to be sold later. A warehouse is usually a space that is specifically designed for storage. It may be owned or rented by the manufacturer. The quality and management of a warehouse affect its operations and the safety of the goods that are stored in it.

Importance to keep your warehouse at its best

It is important that a warehouse be well maintained as well as efficient. A well maintained warehouse will keep the stored goods in their best condition. A poor or unhygienic warehouse could cause damage to the goods being stored in it. It will also allow quick and efficient access to the stored goods when required. Warehouse equipment such as cranes, forklifts and conveyor systems should be in good working order. If any of these systems fail they can cause delays and disruptions in the operations of the warehouse. The time spent repairing equipment would be wanted time and money for the customer whose goods are being stored in the warehouse. So, maintenance of a warehouse is just as important as all the other activities in it.

Tips to maintain your warehouse

Preventive maintenance

Preventive maintenance measures that are carried out regularly are essential to preventing issues before they happen. Some of the preventive warehouse maintenance measures are:

- It is essential to recruit human resources who are trained and certified to operate the equipment in the warehouse. Trained machinery operators will be more efficient. They are also less likely to have accidents and mishaps due to the wrong handling of equipment.

| Common Inventory Management Problems, Challenges, and Solutions | Quick Tips for Buying the Best Inventory Management Software |

- Safety drills should be conducted regularly. All people in the warehouse would have a drill that prepares them for situations such as a fire or evacuation. When the personnel in the warehouse are trained to handle such emergencies, they will remain calm and respond appropriately.

- Implement safety standards that are in line with the best in the industry. Rewarding employees for adhering to the standards is the best way to incentivise them to follow these practices. Enforce best practices such as the prevention of trip hazards and other safety best practices. Hazardous materials should not be allowed into the warehouse.

- Equip the warehouse and personnel with all the safety equipment that is required. Make it mandatory to use helmets, industrial boots and all other safety equipment. The warehouse should also have adequate sprinklers, fire extinguishers and other hazard management and mitigation equipment for use in emergencies. Best practices such as clearly marked exit points and hazard zones are essential. The layout diagrams and the routes to exit should be clearly displayed on all floors and levels.

- Proper and diligent pest control is essential in a warehouse. An infestation of pests can destroy or damage the goods stored in the warehouse. Pest Control methods should be as per the best practices in the industry.

- Make a pest control plan and schedule

- Have regular inspections to detect pests

- Maintain the doors, windows, floors, roofs and other potential access points of the warehouse properly so that pests do not gain access through them.

- Have a cleaning and warehouse maintenance routine

- Use permitted pest repellents and hire a pest control agency for regular warehouse maintenance

- Rearrange goods from time to time to dislodge any pests that are settling in

Planned maintenance

The proper functioning of the equipment in a warehouse is essential to its smooth operations. Equipment that is well maintained is less likely to break down.

- There should be a scheduled warehouse maintenance plan for all the equipment in the warehouse. The replacement dates for components of machinery and equipment should be recorded and adhered to. When items such as seals, filters and oils are replaced on schedule, it enhances the life and condition of the equipment. This is difficult to do unless there is a scheduled down time for each piece of equipment. It is not possible to perform service and maintenance for all the equipment at the same time without affecting the operations of the warehouse

- Some equipment is best managed by the manufacturers. Annual maintenance contracts (AMCs) with the manufacturers or service providers are essential for the maintenance of these pieces of equipment

- Larger warehouse operations have a lot of machinery and equipment and manually monitoring their maintenance and repairs is cumbersome. A warehouse management system that has a CMMS software (Computerized Maintenance Management System) module will help store, track and update the warehouse maintenance records of the equipment and generate reports

- The cleanliness and hygiene maintained in a warehouse keeps goods safe and is important for the health and safety of employees

Employee feedback

The employees who work in the operations of the warehouse are the best people to provide valuable information and feedback on the operations and the equipment. They can tell you where the bottlenecks in the operation are hampering better efficiency. If there are issues with equipment or a better way to use them, employees will be the first to let you know. Employees who feel cared for are also more likely to be invested in the operation and improve productivity and safety.

How organising and tracking inventory at warehouse helps?

A warehouse can be used by many different companies to stock their goods. It could also be used to stock different types or batches of goods for a single company. When there is no organization and record of the stock within the warehouse, employees have to manually and visually locate the goods that are required. This is a huge waste of time and human resources.

An organised warehouse is more efficient and safe. When you keep the warehouse organised you can very easily locate and move any goods that you need to. Knowing exactly where goods are stored is important so that employees do not waste time trying to locate goods. Good planning also prevents confusion and traffic jams of things coming in and going out through the same access path. Well organised layouts and wide access paths keep goods moving smoothly.

Does inventory management software help you manage inventories at warehouses?

Some of the benefits of warehouse inventory management software are:

- An integrated business and warehouse management system such as Tally helps you track stock, locate goods and also track the quantity of inventory. This improves the productivity of the employees and the efficiency of the warehouse. It also makes it easy to account for the movement of goods in and out of the warehouse along with the relevant invoices and reports

- The automation of routine tasks improves the productivity of the employees

- Automated warehouse maintenance records keeps equipment in good working order

- You have accurate, real time reports and information about the stock of goods in the warehouse

- Software that generates reports over time helps you study trends and patterns

- Inventory location tracking improves the speed and efficiency of operations

- Records of cycle counts and audit information are kept to verify the actual count of goods and prevent theft or malpractice

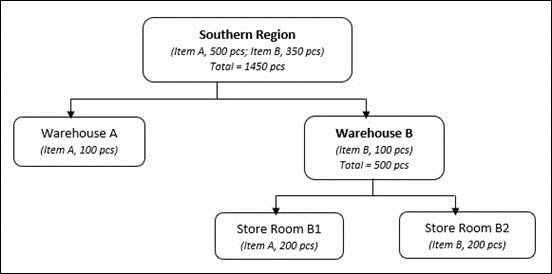

- If you have a hierarchy of warehouses within a location, Tally’s warehouse management system allows you to create the same. This helps you manage different physical locations within the same warehouse complex

Hierarchy of warehousing in TallyPrime

- If you have multiple warehouses within the company, Tally’s warehouse management system helps you track goods movement between the warehouses

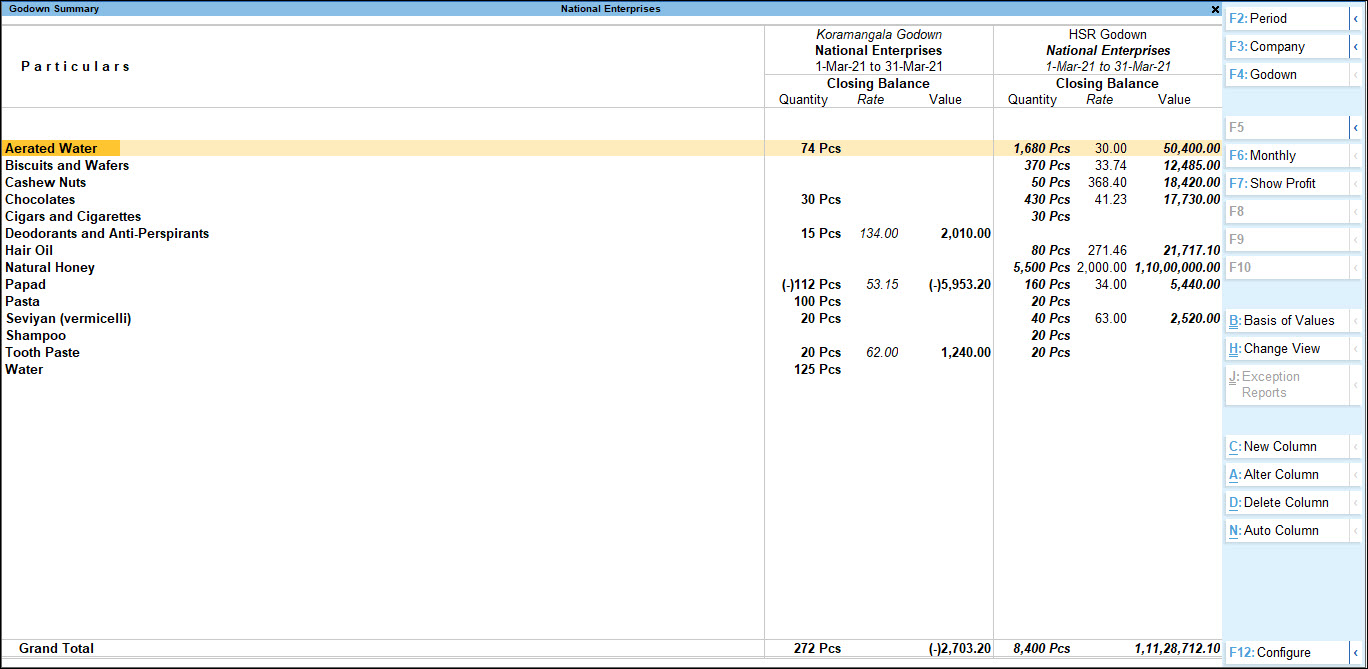

Inventory management through software makes warehousing less chaotic and supports efficiency and smooth operations. TallyPrime is a fully integrated accounting and inventory management software that helps you store, record and track inventories at multiple locations or warehouses. Using TallyPrime, you can easily handle the stock transfers between various godowns and the insightful reports help you a birds-eye of view of stock at different locations.

Warehouse summary report in TallyPrime

Watch Video on Warehouse Management

Read more: