- Top challenges in managing inventory

- How inventory management software can help you overcome challenges

Inventory management is an essential process in many different businesses ranging from retail sales to manufacturing industries. Good inventory management is crucial to the success of these businesses. Better inventory management improves cash flows and reduces expenses. Some inventory management problems are common across industries.

Top challenges in managing inventory

Visibility problems

When your inventory becomes hard to find, you have inventory visibility problems. Lack of visibility is one of the most common inventory management problems. Locating the correct item in the right place as quickly as possible is essential to inventory. If the hard to find inventory is part of the supply chain for manufacturing, it can impact the operations of the entire manufacturing process. If the inventory stock is being accessed for shipping and cannot be located, it leads to incomplete or wrong shipments and severely impacts customer satisfaction. Either way inventory visibility problems have a severe impact on the performance of the business and is one of the symptoms of poor inventory management.

| Top 5 Inventory Management Reports | Best Inventory Management Software for Businesses |

Lack of real-time reporting

Inventory reports are essential to making decisions. An inventory department cannot summarise and report based on real-time inventory data when using a manual system. Reports on historical trends are also challenging to prepare quickly. When management cannot visualise inventory stock or trends, making informed decisions on purchase and inventory becomes tough. This directly affects the bottom line of the company.

Inefficiency

Managing inventory manually is a cumbersome and tedious process. Even the routine tasks become slower than they should be. As companies scale up, the process becomes more inefficient and slow. Manual inventory management becomes even more challenging to implement across multiple warehouse locations. Inefficient inventory management slows down operations. Inventory management problems that cause slow shipping of products leads to a fall in customer satisfaction. Even when software solutions are used, improperly designed or obsolete systems do nothing more than merely replicate the manual process of inventory management. Inefficiency and redundancy are some of the symptoms of poor inventory management.

Overstocking

Money that is spent on inventory gets locked in if the items are not used. Overstocking can impact the profitability of a business. This is because more stock is bought than being sold. Management of inventory to stock the correct quantity of items is essential to a company’s financial well-being. Overstocking also results in the buildup of obsolete stock. This is the material that has been bought or stocked in excess and is no longer in demand. In a manual system, this stock may be abandoned or forgotten. When it is in demand again, the company may buy more of it instead of using what is already stocked.

Understocking

Being understocked is also one of the inventory management problems. In manual systems, the flagging of materials that need to be reordered is dependent on the vigilance of the people managing inventory. When there is a slip-up, the company may find itself understocked to meet demand. In a supply chain, inventory management feeds the entire production process. Understocking can slow down production or even bring it to a halt. Not utilising the available warehouse space is also money wasted. Improper inventory management does not make the best use of all the available warehousing space that the company is paying for or bearing overheads on.

Lack Of trend forecasting

Trend forecasting is essential to managing a business. Projections and forecasts for inventory stocks are accurate when based on actual numbers and trends. Manual systems cannot quickly deliver summaries and reports. Inaccurate forecasting of trends could also lead to the company not anticipating seasonal rises and falls in demand. Lack of historical data to forecast trends is essential to avoid both overstocking and understocking.

Lack of centralization

Centralisation is not a problem in smaller businesses, with all their inventory stored in one location. As companies grow, they expand their inventory to different locations. Manual maintenance of inventory records makes it very difficult to communicate and access inventory data across locations. Manual reports and lists do not show the real-time stocks of inventory. Disconnected data is often a cause of delayed or incorrect shipping. It is also impossible for management to get an accurate real-time report on all their inventory across locations.

How inventory management software can help you overcome challenges

Improved visibility and transparency

Implementing an inventory management solution such as Tally helps you easily locate any item that is required. It also gives you complete data about the required item and its availability. Being able to locate inventory items improves the efficiency of the company. At the management level, the ability to visualize inventory helps in better decision making to streamline the process. Managers can easily visualise past trends and base their forecasts and planning on actual numbers.

Increased customer satisfaction

More transparency also allows the company to measure the efficiency of their inventory management. They can see how the stocks flow through the system and identify bottlenecks. In companies that ship to the customer directly from inventory, customer satisfaction based on shipping speeds can also be measured. Accuracy in identifying and shipping items will also enhance customer satisfaction.

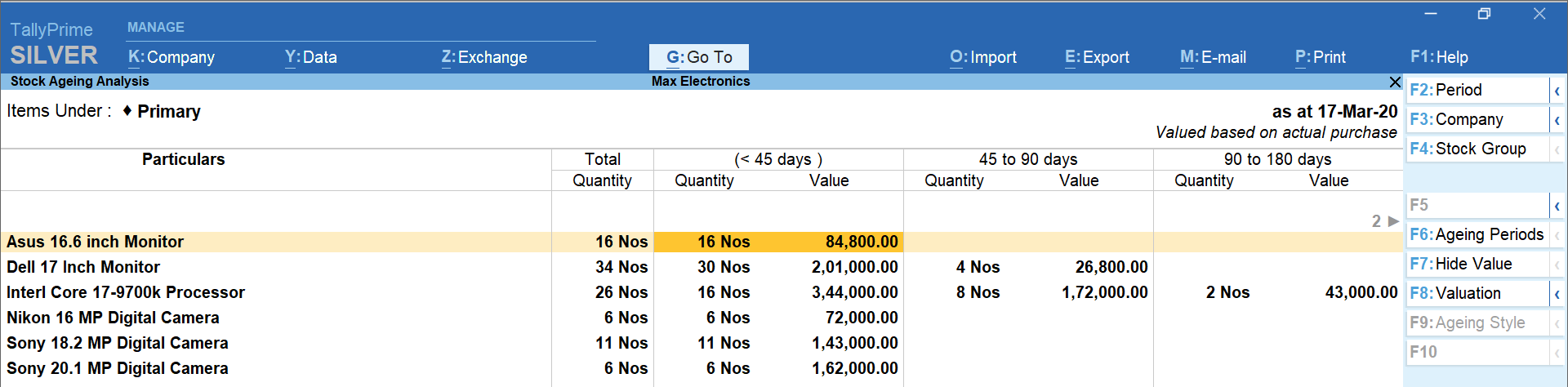

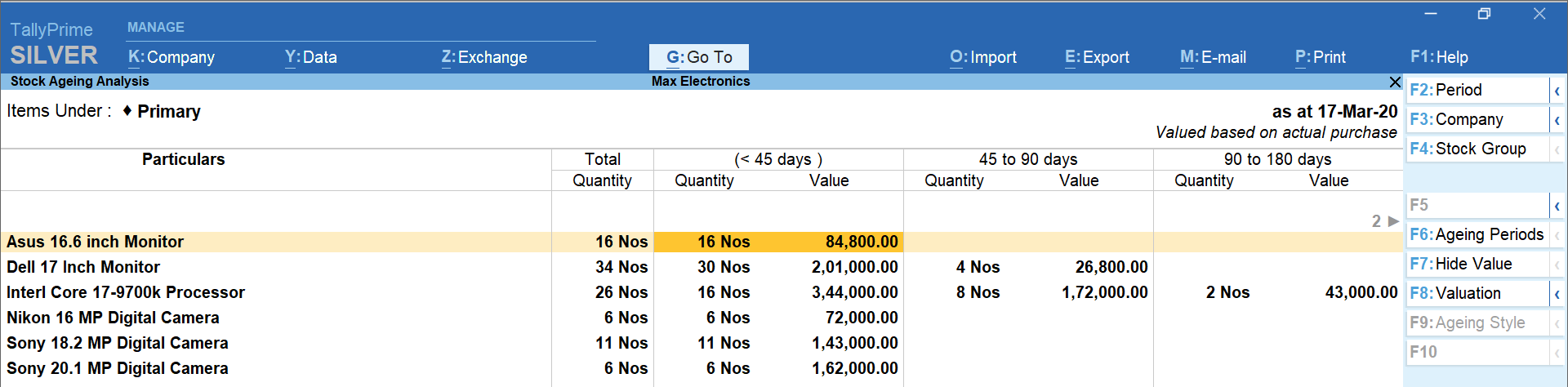

Stock analysis in TallyPrime

Increase in productivity

Inventory management software improves the efficiency and productivity of all the personnel involved in inventory management. Any inventory items can be easily found without having to search manually. Scaling up operations does not cause inventory management problems when you use an inventory management system. Computerised inventory management also lets you go paperless if you want to.

Accuracy in recording and tracking inventories

Management of stock through inventory management software reduces human error and provides accurate and up to date data. A computerised inventory management system such as Tally lets you know exactly where your inventory items are. Inventory data is updated and accurate in real-time.

Easy to manage and track inventories

When you use an inventory management system such as Tally, you have a better handle and control over the stock levels. You can easily track items that are being unnecessarily stockpiled. Even if you have obsolete inventory, it is tracked by the system to avoid buying more of what you already have.

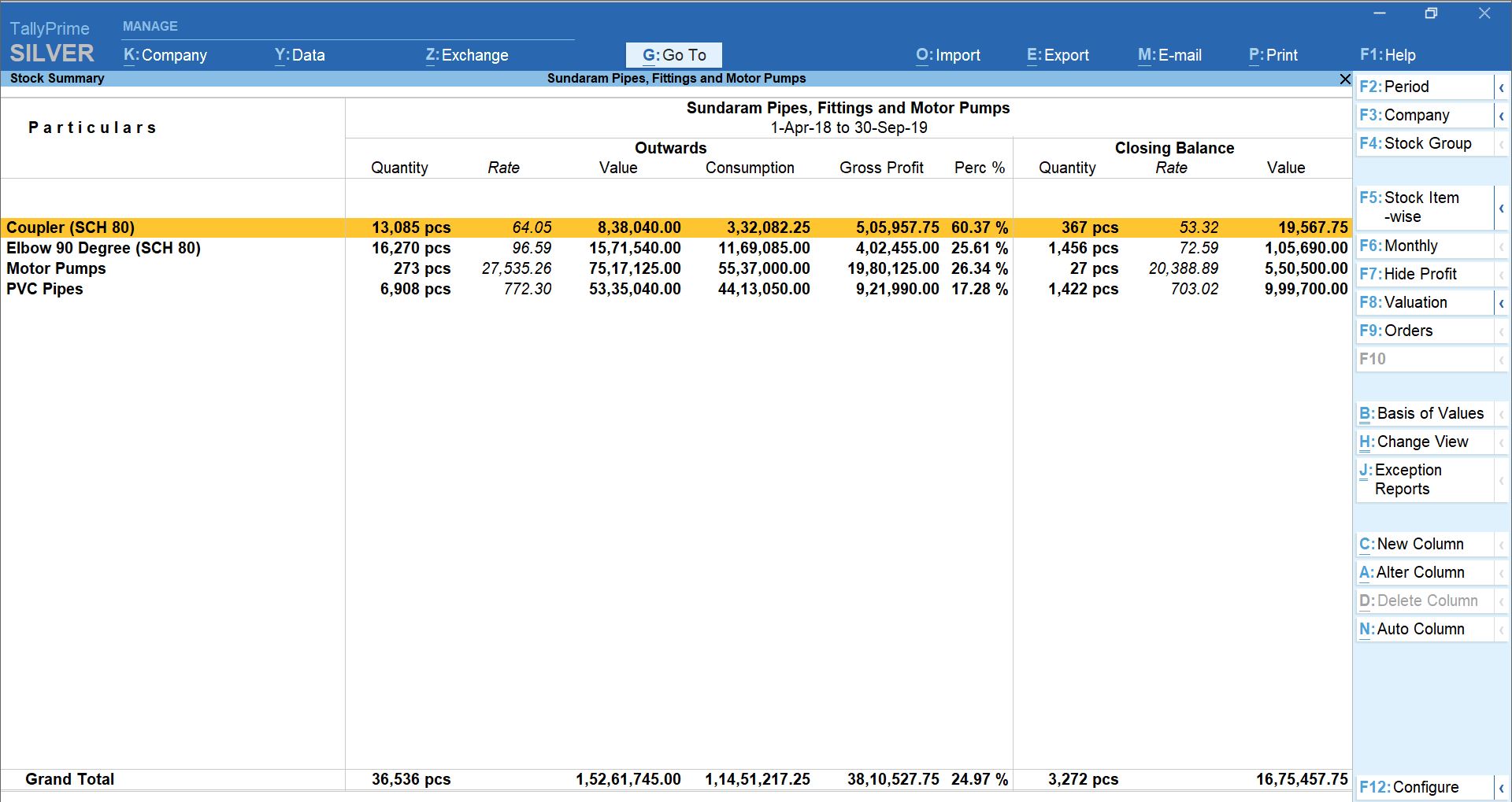

Get to know the fast-moving and high profitable inventories

When you can visualise and study the inventory movement and profit margins, it helps you identify fast moving items as well as items that fetch you a better profit margin.

Stock item-wise profitability analysis in TallyPrime

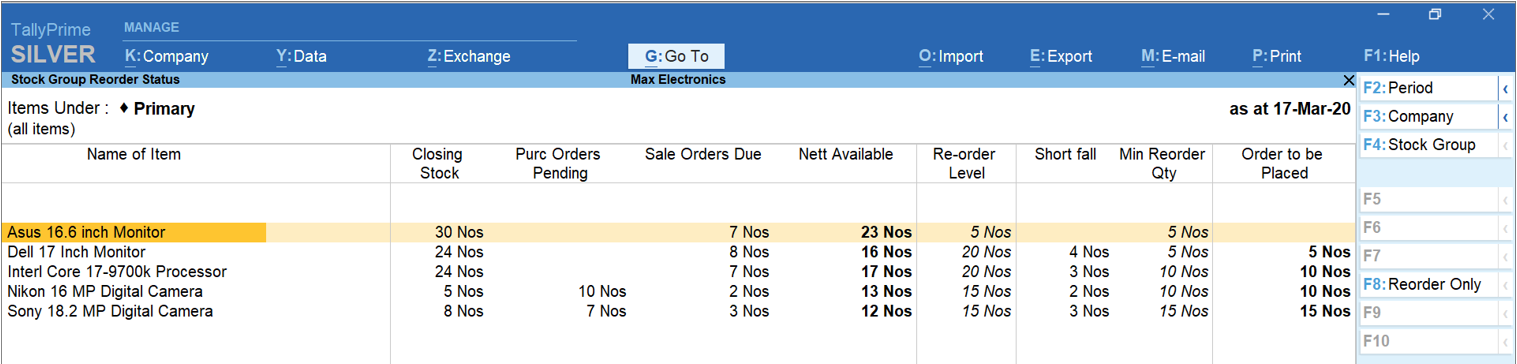

No worries of understocking and overstocking Of inventories

Inventory management shows you the items that are falling below the set reorder level. You can promptly order the required materials so that you do not fall short.

Reorder Levels On TallyPrime

Insights from reports help you in on-time business decisions

The easy access to reports that analyse inventory over time also empowers the company to better forecast trends and manage inventory accordingly. Decision making in the company becomes fact driven.

Connectivity and centralisation

Management of inventory through an integrated solution such as Tally helps in the centralisation of the inventory data. It also allows the inventory data to flow seamlessly between locations. So, the system is quick and efficient even when something has to be shipped out of inventory across locations. Tally also helps monitor inventory in different storage areas. Inventory can be easily managed across different warehouses within the same location or across geographies.

Cost optimization at all level of inventories

Inventory management through software such as Tally is also a good cost control measure. Efficient inventory management prevents mishaps such as overstocking that locks up precious capital. Software enhances the productivity of inventory management and warehouse personnel. Software also lets you use your warehousing space optimally. Empty and unused warehouse space is a waste of money that can be prevented by properly visualising and locating stock.

Help you get rid of the risk Of old And expired Stock

Goods that sit in inventory too long are a waste of money too! Efficient inventory management helps you attain that perfect balance of inventory to reduce costs and increase profits.

Switch to a smart integrated business solution with inventory management such as Tally to make the most of your inventory and warehousing processes. It will make a big difference to the efficiency, productivity and profitability of your business.

Read more: